Aakash Dammala

Full Stack Robotics Engineer

👤 About

I'm a Robotics Engineer with over 3.5 years of experience in Autonomous systems development. Currently pursuing my Master's in Robotics at the University of Maryland, College Park.

My expertise spans multi-agent fleet management, path planning, navigation, simulation, hardware interfacing and control. I've worked extensively on Level 4 Autonomous delivery robots at Ottonomy.

As an early engineer at a high growth startup, I got to contribute to many things, from controlling a BLDC motor to managing international robot deployments, scaleing from prototypes to deployments across 10+ countries.

💼 Experience

Multi-Robot Fleet Management & Optimization

- Engineered a multi-robot task allocation system utilizing Mixed Integer Programming (MIP) and Large Neighborhood Search (LNS) to optimize delivery sequences, significantly reducing fleet idle time and delivery latency

- Developed a discretized topology graph generator using a circle-filling algorithm to convert navigable areas into interconnected nodes, pathfinding for large-scale multi-robot coordination

- Built C++/REST API interface, establishing a robust communication layer between the central fleet server and distributed robot agents

Navigation & Autonomy

- Optimized the local planner for high-speed navigation, refactoring the codebase for multi-threading to boost control loop frequency to >25Hz, enabling stable tracking at higher velocities

- Deployed a decentralized collision avoidance system using shared reservation tables to prevent deadlocks in narrow corridors without a central coordinator

- Implemented a visual-servoing based Auto-Docking system for delivery robots, using Aruco markers and nonlinear PID controller, achieving 2.5cm / 3.0° pose accuracy with a >99% success rate across 300+ trials

Drive Control & Kinematics

- Architected the core Drive Control System for the Ottobot v2.0 swerve-drive platform using C++ and ROS; designed a modular kinematic engine that supported rapid prototyping of Skid-Steer, differential drive and Ackerman mechanisms

- Developed real-time motion control firmware, implementing forward/inverse kinematics and multi-axis synchronization for BLDC and Servo controllers, ensuring precise trajectory execution

International Deployments

- Saudi Aramco HQ (KSA): Solely responsible for managing the full lifecycle, from installation to operational handover of delivery robots. The successful pilot secured a strategic partnership and future contracts with Aramex in the Middle East (May - Sep 2023)

- NEOM city, Oxagon Project (KSA): Managed fleet operations for a multi-robot deployment, conducting high-stakes technical demonstrations for stakeholders and led client acceptance testing for new features (Oct 2023 - Jan 2024)

Other Development Tasks

- Developed a pipeline to integrate multiple depth cameras (Intel RealSense) for navigation and obstacle avoidance by fetching, pre-processing and merging point clouds from multiple sensors

- Developed Python-based touch screen HMI for robots to facilitate operators to debug and for customers to collect orders

- Set up Gazebo & Stage simulators, capable of supporting multiple robots, dynamic obstacles, and various drive types, and wrote controllers for swerve and Ackerman drives

- Simplified and streamlined the process of software installation and testing in the robot's assembly line by breaking it down into smaller, well-defined tasks. Achieved a throughput of 5 robots per week with a 2-person team

Learned and applied various Lean manufacturing techniques on suspension manufacturing lines to reduce quality errors. The final project addressed a recurring production line issue through the implementation of the Poka Yoke technique.

Hands-on learning with advanced precision manufacturing machines and tools, including Wire EDM, 5-axis CNC, CNC Lathe, VMC and CMM. The final project involved designing an aerospace component in Siemens NX, writing G & M codes manually as well as generating using CAM software, and machining the component using CNC turning.

🚀 Projects

View all →

December 12, 2025

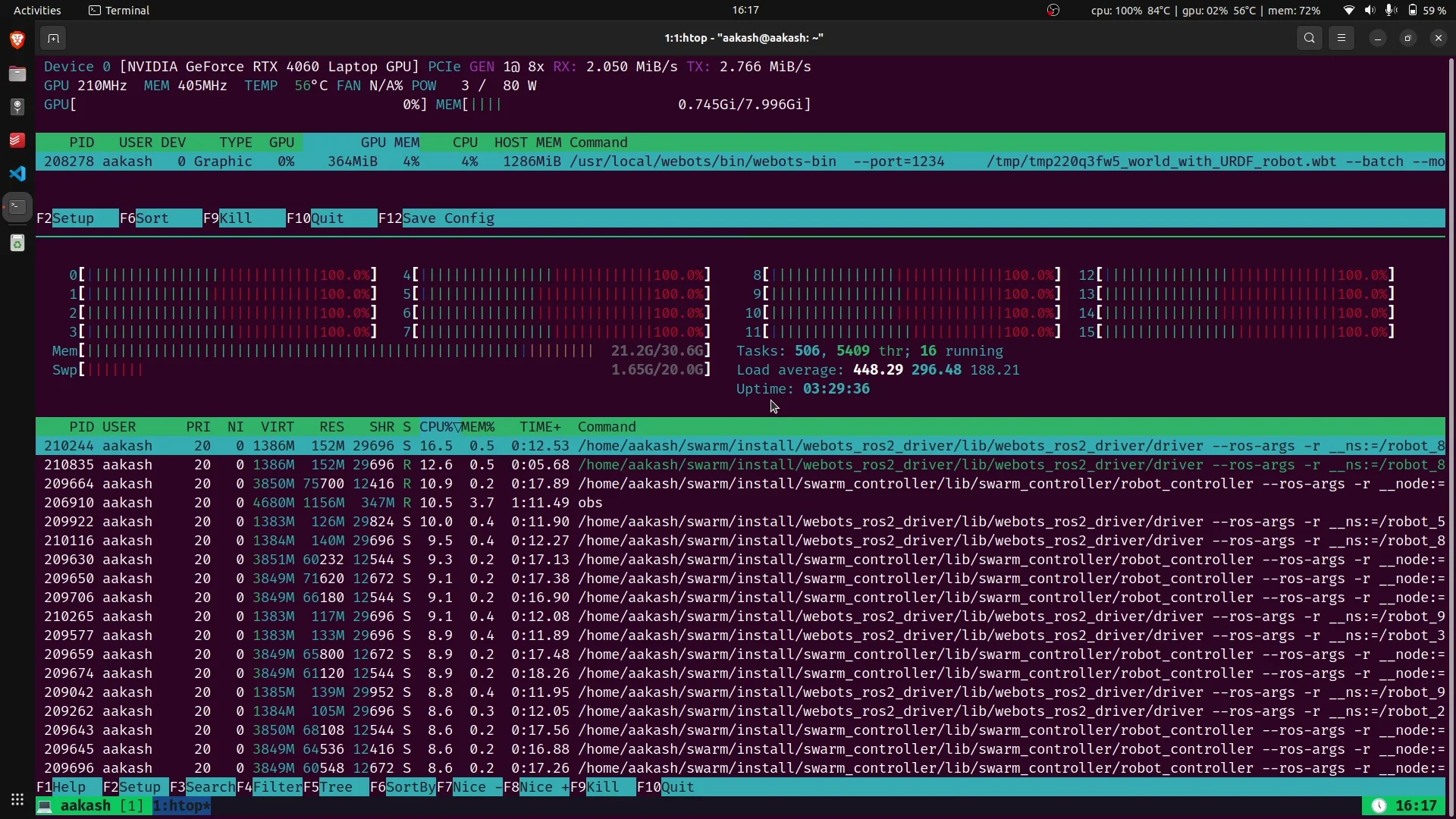

Finding the Limits of Webots Simulation: How Many Robots Can You Simulate Simultaneously?

A stress-test of Webots simulator with 100 autonomous robots performing hazardous waste collection and disposal.

November 29, 2025

Comparing Lateral Controllers for Self-Driving Cars: PP vs LQR vs MPC

A hands-on comparison of Pure Pursuit, LQR, and MPC controllers for path following in CARLA simulator.

December 15, 2024

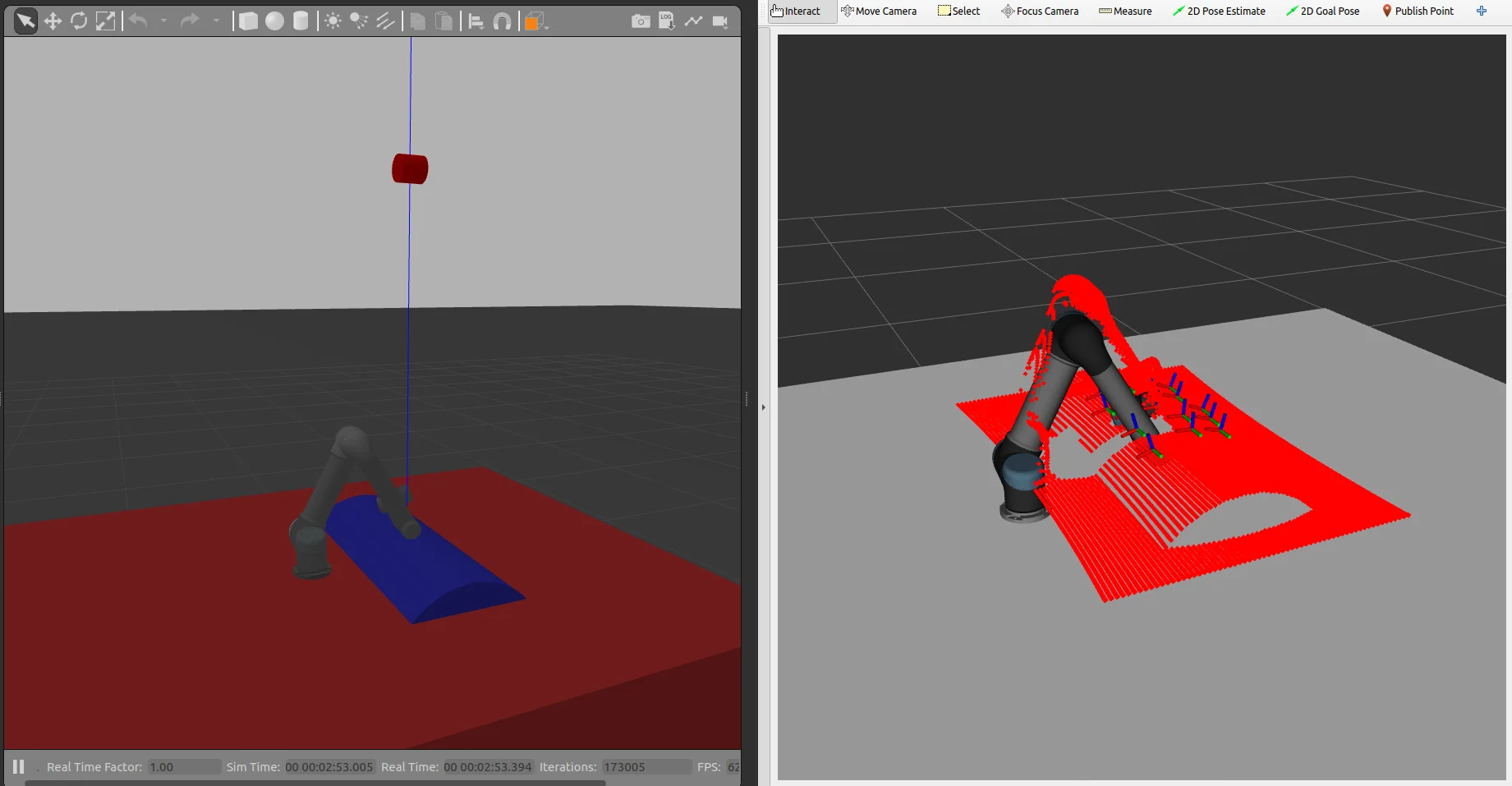

Surface Painting Robot (3D Perception, Planning, Inverse Kinematics)

A ROS 2 system that scans objects with LiDAR, plans coverage paths, and executes painting trajectories on a UR5 manipulator using Jacobian-based IK.

June 15, 2024

Under Construction

More projects are coming soon!

📄 Publications

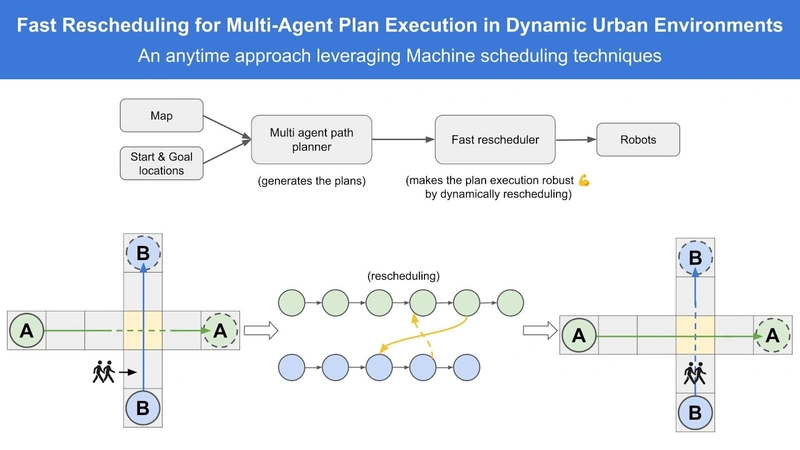

Fast Rescheduling for Multi-Agent Plan Execution in Dynamic Urban Environments: A Machine Scheduling Perspective

- Formulated the multi-robot rescheduling problem as a Blocking Job Shop scheduling problem, to address dynamic constraints in complex urban environments

- Developed an Anytime Local Search algorithm capable of real-time rescheduling, greatly reducing computational overhead compared to exact methods, while minimizing global delay and providing high quality solutions for large scale deployments

💡 Patents

Tether Tension Monitoring System

A 2-part safety device for tethered Aerostats, that monitors the

tension in the tether, and wireless notifies ground the station in

case of any anomaly. It also has a mechanism to safely deflate and

release hydrogen gas present in Aerostat to avoid any accidents.

Developed at IIT Bombay's Lighter Than Air (LTA) Lab, under

guidance of Prof. RS. Pant

Portable Device for Measuring Wood Hardness

A portable device to perform the Janka hardness test (hardness of

wood) without the requirement of cutting down the trees for collecting

samples

Developed under guidance of Prof. AK Prasada Rao

Automatic Electric Iron Power Switching Device

A retrofit device that automatically powers off electric irons when

idle, reducing energy consumption and preventing fabric or ironing

board burns

Developed under guidance of Prof. Rajiv Dey

🎓 Education

Relevant Coursework: Software Development for Robotics, Introduction to Robot Modeling, Control of Robotic Systems

Relevant Coursework: Manufacturing Processes, Kinematics and Dynamics, Machine Design, Operations Research, CAD & CAM, Automation, Programming in C++ and Python

🛠️ Skills

Programming Languages

Robotics Middleware & Libraries

Simulators

Embedded & Hardware

Software Engineering

🏆 Awards & Honors

Circle of Excellence Honor

For exceptional contributions that endure beyond tenure. Award given to me, 9 months after leaving Ottonomy, recognizing lasting impact on the company.

Key Contributor

As the Vice President of University Robotics Club, I represented university in many national robotics competitions and hackathons, organised robotics events at the annual university fests and actively contributed to the club's success This award was given to me by Dean Student welfare, Col. Mohit Bawa, recognizing my contributions

🌍 Outside Work

Beyond work, I'm passionate about adventure and endurance activities. I enjoy cycling, running, trekking, skiing, swimming, paragliding, river rafting, and other such activities.

I am currently training to participate in the Ironman 70.3 triathlon.